KC PREMIER PLATES APPLICATIONS DATA

Effective lapping process is dictated by the proper lapping plates. The choice is controlled by the final objective such as: stock removal, smooth finish, the material being lapped and equally important, the diameter type/size mixed in the proper slurry.

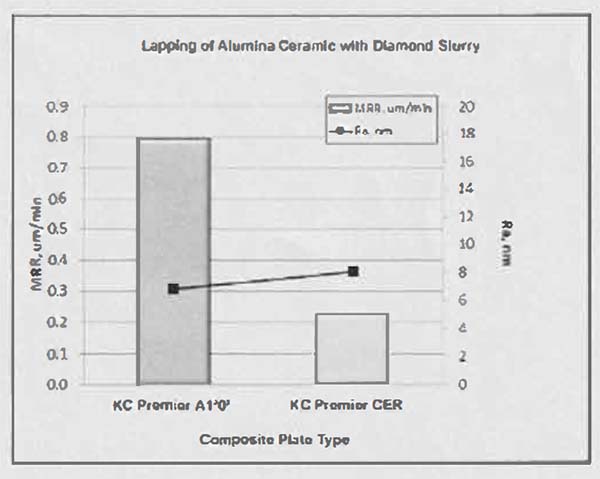

Composite lapping plates allow for effective "charging" of the diamond in the plate. The "charged" plate can greatly enhance process time and achieve a better result, sometimes in a single step.

- KC-PREMIER KFe2+O3

Composite Iron that is most forceful in stock removal: excellent alternative to cast Iron. - KC-PREMIER KCu (OH)2

Composite Copper - versatile - excellent for single step operations. - KC-PREMIER KAI2O3

Composite Aluminum - A perfect alternative to the KCu (OH)2 plate if Copper contamination is a problem. - KC-PREMIER KSn2

Composite Tin - The Tin produces a very fine finish achieving flatness. In some situations the Tin can minimize or replace pad polishing. - KC-PREMIER CER

Composite Ceramic - It is an excellent alternative when the process requires metal free.

- KC-PREMIER PLATE PATTERNS

- Sizes - 1 inch to 100 inches OD.

- Available mounted to a solid metal base or unmounted.

- Groove Options - Concentric, Radial, Spiral, Square and Custom.

- MATERIAL REMOVAL FROM HIGH TO LOW

- Ceramic

- Iron

- Copper

- Aluminum

- Tin